SIMBUILDER

SIMBUILDER is the EicasLab tool specifically conceived to support system modelling and control design.

Related Features

Related Modules

Related Brochures

SIMBUILDER OVERVIEW

The SIMBUILDER tool is available in the EicasLab base.

The SIMBUILDER tool provides a complete and professional support to the overall control design process, offering pre-organised structures and architectures specifically devoted to system modelling and control design.

SIMBUILDER Highlights

- Professional approach for supporting the overall control design process

- Pre-organised environment for addressing multi-processor architectures and multi-hierarchical controls

- Professional support for system modelling and control design

- Advanced activity scheduling

- Wide offer of programming modes for high flexibility and any level of control complexity

A PROFESSIONAL APPROACH FOR SYSTEM MODELLING AND CONTROL DESIGN

EicasLab has been conceived and developed as a professional software suite supporting the automatic control design in all its phases and allows developing and testing embedded control system architectures at different hierarchical levels.

SIMBUILDER offers a professional approach to the control system design, giving special attention to the control hardware and software architecture, where multi-processor and multi-level hierarchical controls are considered.

PRE-ORGANISED WORKING AREAS

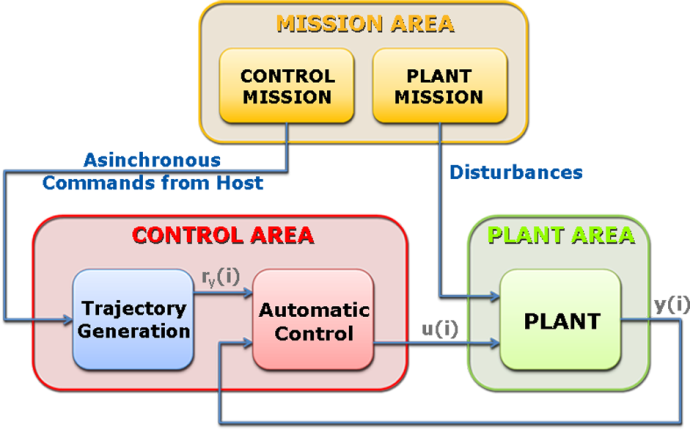

The SIMBUILDER tool is an environment where the designer can develop all the algorithms and software related to the "plant controller", including both the "automatic control" and the "trajectory generation".

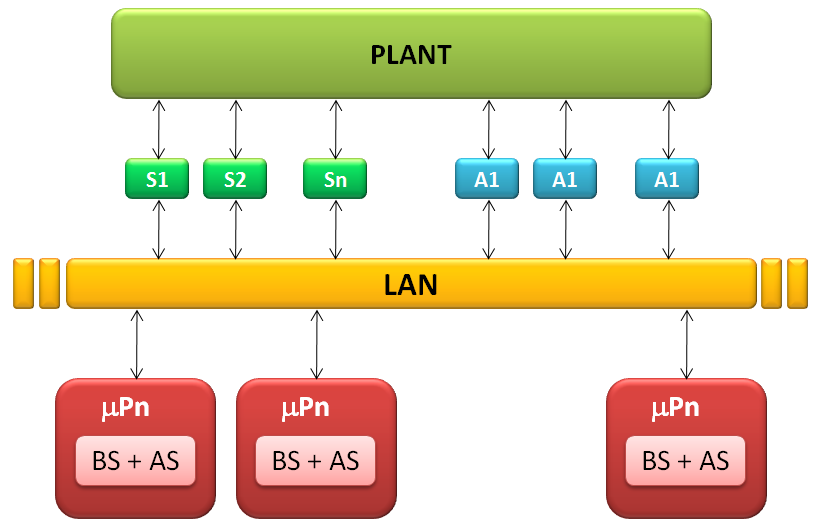

To perform such a task and to facilitate the user in the design and development of the control system architecture the SIMBUILDER tool provides three main Pre-organised Working Areas, specifically devoted and customised to program the different parts of the project:

- the Plant Area, for modelling the plant to be controlled;

- the Control Area, for the implementation of all the control algorithms;

- the Mission Area composed by two parts, respectively:

- The Plant Mission, devoted to generate the disturbances acting on the plant;

- The Control Mission, devoted to generate the references of the highest hierarchical level for the control.

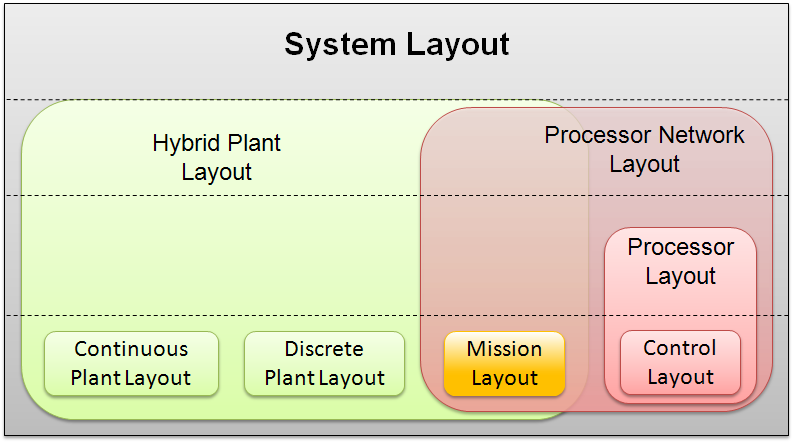

HIERARCHICAL LAYOUTS AND LIBRARIES

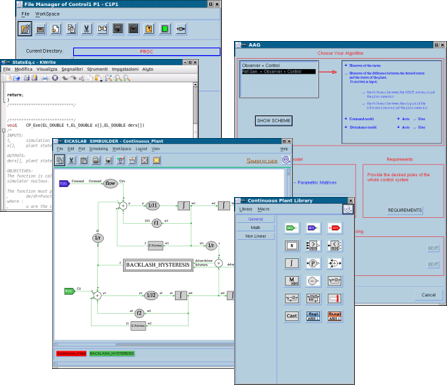

SIMBUILDER is focused on the concept of “Graphical Layout”, that represents a graphical space devoted to system programming. A set of graphical layouts organized in hierarchical levels are available for each pre-organised Working Area (Plant Area, Control Area, Mission Area).

Each Graphical Layout is devoted to a specific task (f.i. plant modelling, control design) and it is equipped with a specific and oriented library window which contains a set of libraries composed by blocks.

In particular, the user has at disposal libraries providing blocks that implement mathematical models with different levels of accuracy, taking into account nonlinear effects, such as hysteresis and friction, that are crucial and not negligible aspects in the control system design.

Moreover the SIMBUILDER tool allows the user to create its own user libraries containing user blocks programmed in graphical mode or in ANSI C language.

User libraries may be shared among EicasLab users:

- collected in archives protected with password;

- including suitable restrictions devoted to share data preserving each user Intellectual Property Right (IPR). Several kinds of restrictions are available, in order to guarantee different levels of protection, depending on the needs.

Special libraries, on purpose developed and customised for several application fields such as automotive, aerospace, robotics and machine tools, time series forecasting and industrial automation in general, are available on request and complete the wide and highly professional libraries offer available in the EicasLab suite.

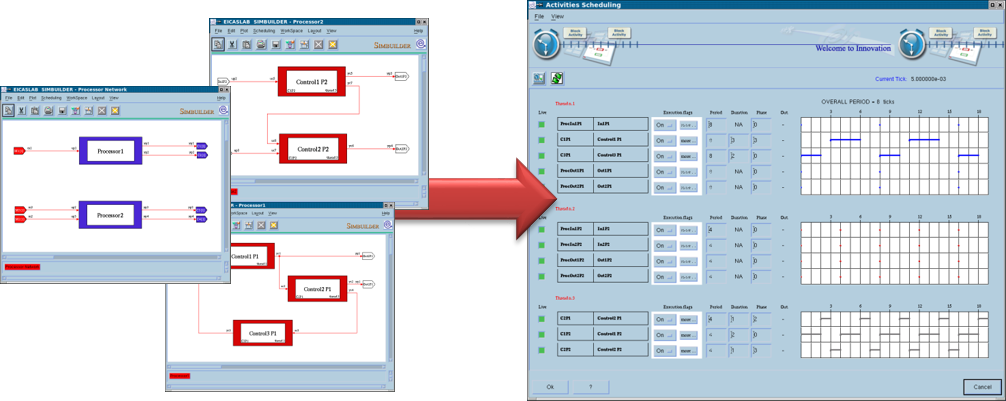

SCHEDULING

SIMBUILDER includes the real-time scheduling advanced feature.

The scheduling of all the activities involved in a control system is a key task for the successful development of the control system itself.

SIMBUILDER provides a fundamental and professional support for a correct scheduling of the system in all the control design phases: it is based on time scheduling algorithms for managing multi-processor and multi-level hierarchical control architectures at any level of complexity.

The core of the time scheduling algorithms is the EicasLab scheduler, which defines the order of the operations to be executed. The EicasLab scheduler is available in the following EicasLab tools:

- SIM tool in Modelling and Like Real-Time operative mode.

- RCP Manager tool in RCP on field operative sub-mode.

- HIL Manager tool in Hardware-in-the-loop operative sub-mode.

- TARGET Manager tool in Final Validation test operative sub-mode.

For each EicasLab operative mode corresponding to a specific control design phase the user has to configure specific scheduling parameters as described in details in the real-time scheduling key feature section.

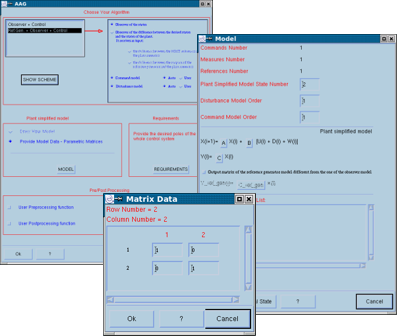

Automatic Algorithm Generation (AAG)

SIMBUILDER includes the Automatic Algorithm Generation (AAG) advanced feature, specifically oriented to design the control according to the EICAS control design methodology.

The designer can choose among three control basic schemes and for each one he has the option of selecting control algorithms at different levels of complexity.

Starting from the control system requirements and from a simplified model of the plant to be controlled, AAG automatically generates the whole control algorithm.

PROGRAMMING MODES

For describing each Working Area SIMBUILDER provides a set of blocks that can be programmed in one of the following modes:

- the graphical mode, where the block is described by means of a graphical layout programmable by inserting in it the blocks of its related library;

- the ANSI C mode, where the block is easily programmable in ANSI C language by means of an open and customisable pre-organized structure that provides a complete set of template files and libraries, allowing to focus only on the specific and crucial aspects to be programmed;

- the library mode, where the user can configure the block by relying on library models available in SIMBUILDER;

- the library and ANSI C mode, where the block is developed through a combination of pre-defined libraries and ANSI C language programming;

- the AAG mode, where the control algorithms are automatically generated by the Automatic Algorithm Generation feature above described.

The wide offer of programming modes available in SIMBUILDER provides the user with all the flexibility for programming control systems of any level of complexity.

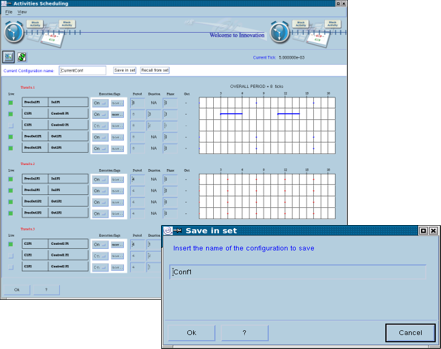

CONFIGURATION MANAGEMENT

EicasLab allows to manage single real-time configuration and multiple real-time scheduling configurations in all the EicasLab operative modes.

The “single real-time configuration” allows performing like real-time simulations in Modelling and Like Real-Time simulation operative mode and real-time executions in RCP, HIL and FVT operative sub-modes with fixed scheduling data.

With the “multiple real-time scheduling configurations”, the user can save real-time configurations containing set of scheduling data corresponding to the list of activities that may be dynamically enabled or disabled by the user on the basis of the occurrence of a given event, either during the like real-time simulations (like real-time configurations) or during the experimental trials executions in RCP, HIL and FVT operative modes (real-time configurations).

The use of the real-time configurations allows implementing higher hierarchical levels of controls similar to discrete-event control systems, such as Fault Diagnostic Isolation Recovery (FDIR) strategies.

Moreover, the user can save in a database data configurations for project backup:

- configurations containing all the project data and source code, useful to a complete project backup;

- configurations containing only the project data, such as all the parameters and the initial states files, useful as project data backup.

EicasLab allows to recall the saved configurations, providing the possibility to retrieve a complete or a partial set of the saved data, depending on the user demand, or to remove configurations from the database.

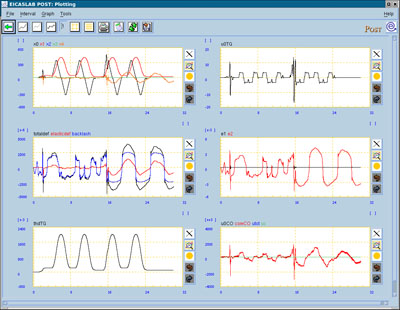

DATA PLOTTING AND RECORDING

During the like real-time simulation and the experimental trials execution, EicasLab allows to visualize, on the PC screen, the dynamic behaviour of a set of predefined variables of interest, by means of the SIM tool for like real-time simulation and of the RCP Manager, Slow Motion, HIL Manager and TARGET Manager tools for experimental trials execution. Moreover, EicasLab allows recording on the PC disk sets of predefined variables for accurate post-processing data analysis carried out by means of the POST tool.

The selection of the variables for plotting, as well as for the POST recording, is fully carried out and managed through a user-friendly GUI available in SIMBUILDER.

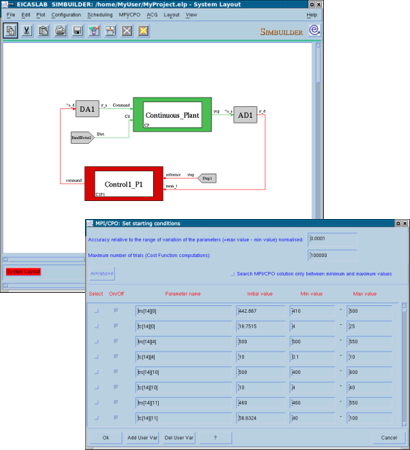

MODEL PARAMETER IDENTIFICATION AND CONTROL PARAMETER OPTIMISATION: MPI/CPO CONFIGURATION

In order to support the user in the control system design phase, EicasLab provides the Model Parameter Identification and Control Parameter Optimisation key features, managed by the MPI/CPO Manager tool that is the powerful tool for performing the model parameter identification and control parameter optimisation. The overall MPI/CPO process may be configured in SIMBUILDER. The MPI/CPO feature is provided by the MPI/CPO module.